Technical Details

Overview Diamond Quality

Diamonds are characterized by the four C’s: Cut, Carat, Colour and Clarity

Source: https://hrdantwerp.com/en/4cs

Cut

The proportions of a diamond define and determine the brilliance and especially the fire of a stone. Diamonds can be polished in various shapes. The shape most commonly used for watches is the round brilliant cut with 56 facets.

Carat

The weight of a diamond is expressed in carats. One carat is equal to 0.2 grams. The carat number refers to the total number of diamonds in a watch.

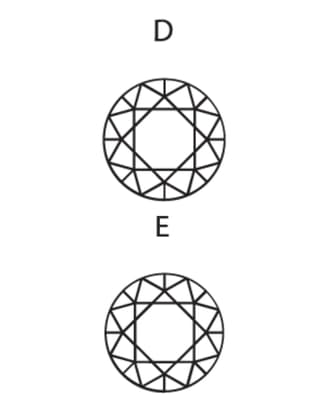

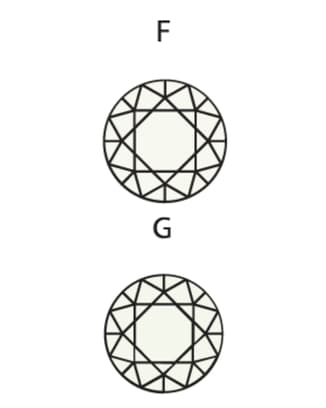

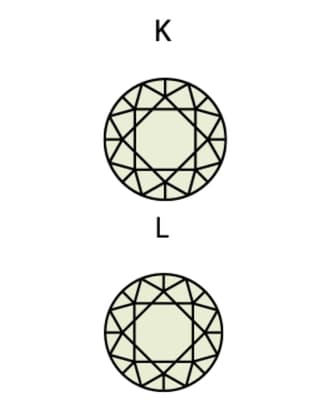

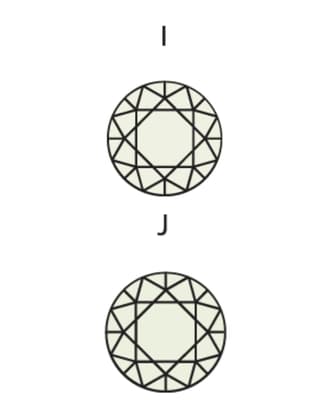

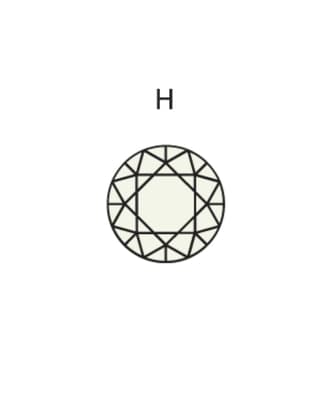

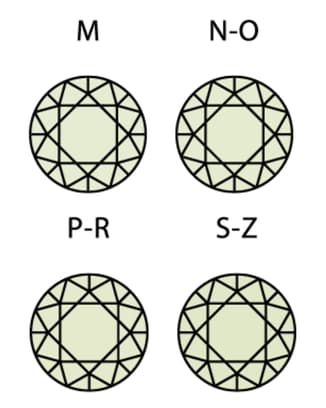

Colour

The majority of diamonds of good quality are colourless (hereafter named white) to slightly yellowish. The colour grade is determined by comparison with a series of masterstones, the best grade being colourless.

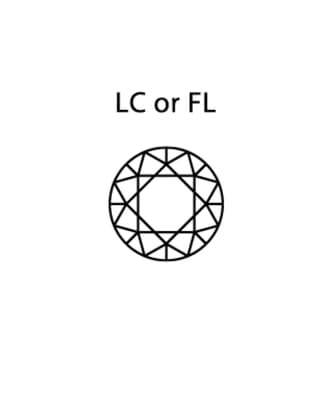

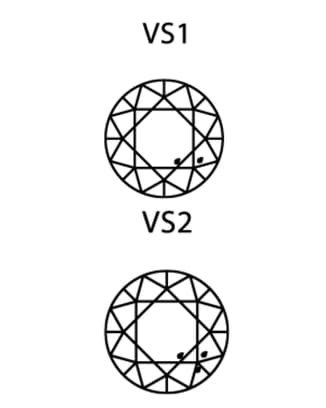

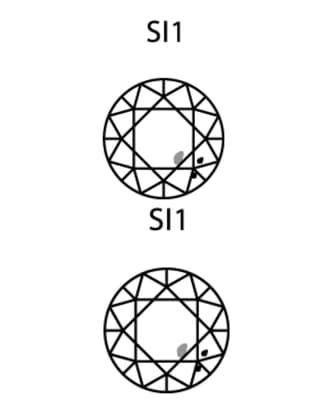

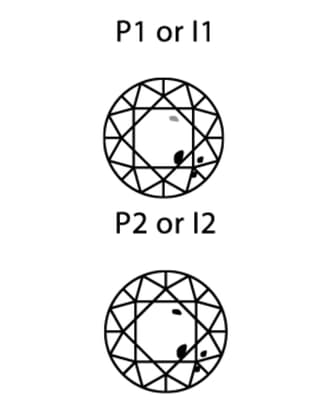

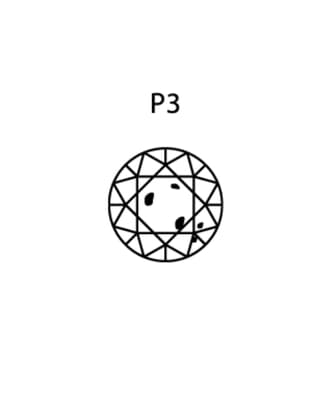

Clarity

All diamonds have traces of their own growth history showing minor internal characteristics. The clarity scale reflects the size, number and location of these characteristics when examined under 10 × magnification. Most inclusions are not visible to the naked eye, and diamonds without inclusions visible to the naked eye are of excellent quality. The rarest and best clarity is called loupe clean – meaning that no inclusions can be found even with a loupe.

Additional Information

System of Warranties at IWC Schaffhausen

IWC Schaffhausen states that all diamonds have been purchased from legitimate sources not involved in funding conflict, and in compliance with United Nations Resolutions. All purchased diamonds are conflict-free, based on personal knowledge and/or written guarantees provided by the supplier of these diamonds.

Use of laboratory-grown / synthetic diamonds

IWC distances itself from the use and processing of synthetic diamonds. Therefore, all suppliers signed a letter in which they gave assurance about not using diamonds created in the laboratory. In order to ensure consistent quality, the diamonds are tested by an independent laboratory.

Fluorescence

Upon irradiation with ultraviolet light, a diamond has a varying degree of fluorescence. This might range from none to very strong. A light fluorescence does not influence the appearance and value of a diamond. However, if the fluorescence is strong, it can make the diamond appear dull in sunlight.

Precious Metals Used By IWC

IWC Schaffhausen is an official member of the Responsible Jewellery Council (RJC) since September 2012. The Responsible Jewellery Council is an international non-profit organization and confederates members from the entire jewellery industry, from mine to retail. RJC members commit to and are independently audited against the RJC Code of Practices – an internal standard on responsible business practices for diamonds, gold and platinum group metals. The Code of Practices sets strict guidelines for ethical, social and environmental practices along their supply chain, as well as to guarantee the protection of human rights. IWC was successfully RJC certified in 2013 and re-certified in 2016.

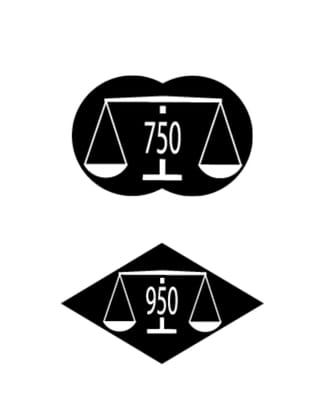

Hallmarks For Precious Metals

Overview Case Materials

STAINLESS STEEL

Scratch-resistance

low ⬤⬤⬤◯◯ high

Breaking strength

low ⬤⬤⬤⬤⬤ high

Weight

low ⬤⬤⬤◯◯ high

BRONZE

Scratch-resistance

low ⬤⬤⬤◯◯ high

Breaking strength

low ⬤⬤⬤⬤⬤ high

Weight

low ⬤⬤⬤◯◯ high

5N GOLD / WHITE GOLD

Scratch-resistance

low ⬤⬤◯◯◯ high

Breaking strength

low ⬤⬤⬤⬤⬤ high

Weight

low ⬤⬤⬤⬤◯ high

ARMOR GOLD®

Scratch-resistance

low ⬤⬤◯◯◯ high

Breaking strength

low ⬤⬤⬤⬤⬤ high

Weight

low ⬤⬤⬤⬤◯ high

PLATINUM

Scratch-resistance

low ⬤⬤◯◯◯ high

Breaking strength

low ⬤⬤⬤⬤⬤ high

Weight

low ⬤⬤⬤⬤⬤ high

TITANIUM

Scratch-resistance

low ⬤⬤⬤◯◯ high

Breaking strength

low ⬤⬤⬤⬤⬤ high

Weight

low ⬤⬤◯◯◯ high

TITANIUM ALUMINIDE

Scratch-resistance

low ⬤⬤⬤◯◯ high

Breaking strength

low ⬤⬤⬤⬤◯ high

Weight

low ⬤⬤◯◯◯ high

CERAMIC (ZIRCONIUM OXIDE)

Scratch-resistance

low ⬤⬤⬤⬤⬤ high

Breaking strength

low ⬤⬤◯◯◯ high

Weight

low ⬤⬤◯◯◯ high

CERAMIC (BORON CARBIDE)

Scratch-resistance

low ⬤⬤⬤⬤⬤ high

Breaking strength

low ⬤◯◯◯◯ high

Weight

low ⬤◯◯◯◯ high

CARBON

Scratch-resistance

low ⬤◯◯◯◯ high

Breaking strength

low ⬤⬤⬤◯◯ high

Weight

low ⬤◯◯◯◯ high

CERATANIUM®

Scratch-resistance

low ⬤⬤⬤⬤◯ high

Breaking strength

low ⬤⬤⬤⬤⬤ high

Weight

low ⬤◯◯◯◯ high

Technical Details

Technical and other specifications may change without notice, and all models and product lines are subject to availability. The information provided here refers exclusively to the model named or is of a general nature. In view of the high degree of craftsmanship involved, all the specifications are subject to production tolerances.

Alloys and Coatings

Ceratanium®

Ceratanium® is made of a titanium alloy, the surface of which undergoes a specific form of heat treatment and is converted into a ceramic coating. This so-called diffusion layer grows on the surface and is not a coating in the conventional sense. As a result, Ceratanium® is particularly resilient and scratch-resistant. It is about 33 per cent lighter than steel and very skin-friendly.

Diamond Shell®

Diamond Shell® is a diamond coating that is applied to mechanical watch components. It is created using the chemical vapour deposition process (CVD for short). This technique allows extremely resistant, thin layers to be produced from a high-quality, high-performance material. These diamond-coated watch components – especially the pallet and escape wheel – reduce friction, make the watch more efficient and increase the power reserve.

Ceratanium® and Diamond Shell® are trademarks of IWC Schaffhausen and are registered in many jurisdictions worldwide.

Armor Gold®

Armor Gold® (hard gold) is a special version of a classic 5N gold alloy that is noted for its improved microstructure with considerably higher hardness values.

Armor Gold® is a trademark of Richemont International SA and is registered in many jurisdictions worldwide.

Glass

IWC exclusively uses sapphire glass for the front glasses and see-through back covers on all models. With a hardness of 9 on Mohs’ scale, it is harder than any other type of glass and topped only by diamond. The glass is made of synthetically manufactured sapphire, which makes it extremely scratch-resistant and less sensitive to impact than quartz (Mohs 7) or apatite (Mohs 5). Many of the sapphire glasses are convex. There are some case designs for which IWC uses convex glass with a distinctly arched edge (also known as crossed-out glass). The antireflective coating reduces glare and gives the wearer a crystal-clear view of the dial.

Jewels

The “jewels” used in wristwatches (often referred to as “rubies” because they are mostly red in colour) are not genuine precious stones. Designed to reduce friction and mechanical wear and tear, they are made of industrial- standard sapphires, usually rubies. They are used for bearings, levers and detents as well as parts of the escapement and the balance and spring, but are also found in certain parts specific to automatic movements, chronographs and minute repeaters. Synthetically manufactured rubies have practically the same physical and chemical properties and are similar in colour to naturally occurring rubies, but their purity and a more homo- geneous crystalline structure give them certain advantages. Depending on the density, hardness, and resistance to pressure and abrasion required, “jewels” may be used that are different from synthetic rubies and/or synthetically manufactured functional jewels. This is due to the materials employed and can create colour differences that result in whitish or transparent stones, for example. As regards their physical and chemical properties, these “jewels” are similar to natural rubies and, after cutting and polishing, have the same surface characteristics.

Ceralume®

Ceralume® is a luminous ceramic made of a persistent phosphorescent ceramic composite material obtained by mixing a conventional white ceramic material with various constituents. One of the constituents is the luminescent material Swiss Super-LumiNova®* purchased from the Swiss technology company RC Tritec. The sintered ceramic composite has physical properties that change obviously the specific characteristics of the appearance of the watch case. In addition to the haptic properties like fine-grained white marble, the Ceralume® material absorbs light energy from sunlight or artificial light, stores it temporarily and then uniformly emits the absorbed energy as visible light due to the effect of the homogeneous phosphorescent material. This cycle can be repeated an infinite number of times in the long term without ever causing the material to age or diminishing its light storage capacity.

Ceralume® is a trademark of IWC Schaffhausen and is registered in many jurisdictions worldwide.

* IWC Schaffhausen is not the owner of the Nivaflex® and Super-LumiNova® trademarks. These marks are protected as the legal property of third parties.

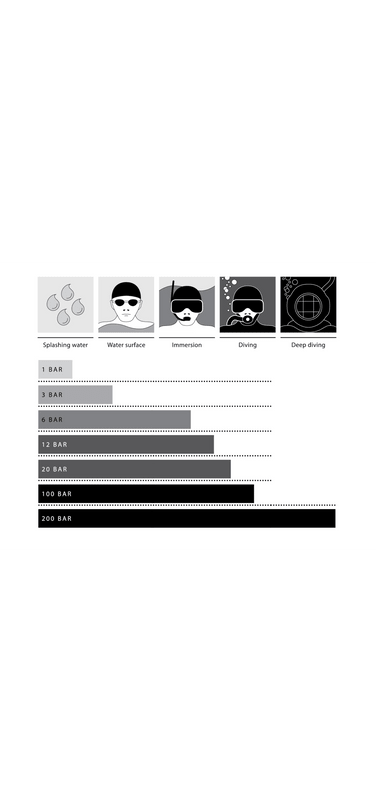

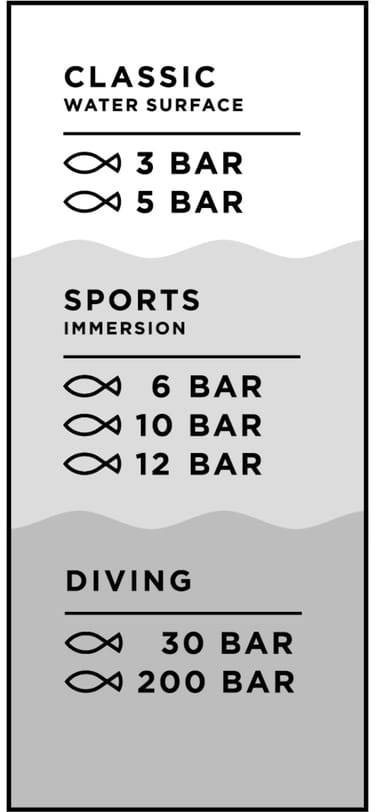

Water-resistance

The water-resistance of IWC watches is stated in bar and not in metres. Metres, which are often used elsewhere in the watch industry to indicate water-resistance, cannot be equated with the dive depth because of the test procedures that are frequently used. The following are some examples for explanation: an IWC watch with an indicated water-resistance of 1 bar is protected against splashing water. With water-resistance of 3 to 5 bar, the watch can be worn when swimming or skiing, and at 6 to 12 bar it will have no problem with water sports or snorkeling. Diver’s watches with an indicated water-resistance as of 12 bar are professional measuring instruments designed for scuba-diving. Special diver’s watches resistant to 100 bar or 200 bar are suitable even for deep-sea diving. The recommended uses for IWC watches, depending on the degree of water-resistance, are established on this basis and on the basis of empirical data, and are indicated in the inserted table here.

Remember that temperature fluctuations and external influences – due to solvents, cosmetics or dust, or caused by shocks, impacts or sudden movements – can fundamentally affect the watch’s water-resistance. Therefore, before engaging in activities that could be potentially damaging to your watch (team sports, high diving, etc.), you are advised to put it in a safe place. Please also bear in mind that not every strap or bracelet is suitable for use in or under water because of the materials used in its construction. Furthermore, with the exception of diver’s watches, the moving parts of the watch (crown, buttons, etc.) should not be operated under water. Before wearing the watch in or under water, you should also ensure that all moving parts are in the “off” position.

It should also be noted that the water-resistance of a watch is not a permanent characteristic. Seals and sealing systems in particular are subject to wear and tear and natural ageing. To care for your IWC watch, please read the operating instructions carefully. After use in or under water, your watch should be rinsed with clear, fresh and lukewarm water and then cleaned and dried. The watch’s water-resistance should be tested regularly, and at least annually, by an authorized IWC Official Agent.

Further instructions for care can be found in the corresponding operating instructions.

Aquatimer Collection:

All the Aquatimer models feature an external/internal rotating bezel that is used to set dive times. The IWC SafeDive® system ensures that the internal rotating bezel can only be adjusted when the external bezel is rotated in an anticlockwise direction. As a result, even if the external bezel is accidentally moved, zero hour – the time at which the diver can return to the surface without the need for decompression stops – cannot be exceeded.

Further instructions can be found in the corresponding operating instructions.

IWC SafeDive® is a trademark of IWC Schaffhausen registered in many jurisdictions worldwide.

Engravings

Engraving Techniques In Brief

Engraving is a cutting process performed on the most varied materials. Its effect is based on the resulting interplay of light and shade, and it can be used to create a wide range of attractive and decorative designs. A variety of engraving techniques can be employed to achieve the desired effects, often of a very personal nature.

Machine engraving

Produces clear lines with lots of contrast and is ideal for an informative, precise representation. It also permits economical and time-saving engraving of relatively large numbers and difficult materials. The lines mostly have a trapezoidal cross-section with an edge angle of about 40 degrees and a depth of about 0.2 millimetres. Machine engraving is particularly suitable for designs that will then be filled in with colour to increase the image contrast.

Line engraving (hand engraving)

Is the technique usually employed for very complex motifs. The technique is similar to that found in copperplate engraving, and the use of various types of cut lends the design a very personal and artistic note. On precious metals, the markings are very bright. By altering the angle of a triangular- shaped tool known as a burin, it is possible to create line widths from very fine to wide. Special emphasis can be placed on individual parts of the motif by hatching or dulling the metal.

Relief engraving (hand engraving)

Is a particularly complex and expressive technique. The effect is reminiscent of that of a coin and is suitable for precious and unique showpieces. By varying the height of the design, the artist achieves a sculpted effect with a strong sense of perspective. A finely cut or polished surface against a matte background serves to intensify the effect.

Individual Engraving

An individual engraving adds to the personality of a watch. We will be pleased to produce a distinctive and unique piece in line with your customers’ wishes. IWC offers a choice of six standard fonts in the common weights (thin, regular, bold, italic, narrow, extended). True Type fonts (PC fonts) are available at extra cost. There is almost no limit to the design possibilities, although not every watch lends itself to intricate engraving. Please contact IWC Schaffhausen directly before accepting an order.

Case

Due to the high level of manual craftsmanship involved, all the specifications are subject to production tolerances.

Anti-magnetic Watches

Anti-magnetic watches are watches whose components have been specially protected or made insensitive to the negative effects of magnetic fields using technical solutions. Magnetic fields have been increasing significantly in number and strength in our everyday lives for years. Electrical devices and, in some cases, extremely strong permanent magnets (such as those found in smart devices or smart device covers) generate magnetic fields that can affect the rate of mechanical watches. It is therefore recommended to keep mechanical watches away from such magnetic fields. Should the watch nevertheless become magnetized, it can be demagnetized again by a specialist using the appropriate equipment at the nearest IWC service centre. Find an IWC service centre: https://stores.iwc.com.

Straps

At your request, we can deliver leather straps with hypoallergenic innermaterials. For aesthetic reasons and to make the watch more comfortablento wear, IWC offers two types of strap in at least three lengths.

Cites

IWC Schaffhausen only uses alligator leather which is fully compliant with the Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES). CITES is the name of a convention and an international organization, both of which aim to control the international trade in animals and plants to ensure that their survival is not endangered. In line with the relevant national and international standards and conventions, all alligator leather used by IWC complies with the CITES convention and is solely derived from alligator farms. Accordingly, IWC does not process any leather from endangered species and only works with leather from alligators reared on farms. The watch manufacturer only uses alligator leather from US farms for its exclusive leather straps. The farmers collect the alligators’ eggs each summer, then they incubate the eggs and raise the hatchlings. After a year or two, 17 per cent of these alligators are then released into the swamps. This equates to the percentage of eggs that would be most likely to be produced by alligators capable of surviving in the wild. This process ensures the survival of the species.

IMPORTANT NOTICE: All our leather products and straps sold in California comply with the legal provisions stipulated by the State of California.