World of watches

KLAUS AND BÜHLER – TWO MINDS, ONE CRAFT

TUNE IN AS WATCHMAKERS KURT KLAUS AND MARKUS BÜHLER CHAT ABOUT THE ART OF WATCHMAKING – THEN AND NOW. DON’T MISS THIS TIMELESS CONVERSATION.

By Elisabeth Gruender

Whether it’s cooking something delicious or going for a walk around Schaffhausen, Kurt Klaus loves the simple pleasures of life. Not too long ago, he was always accompanied by his four greyhounds – well-known to every staff member at IWC. These days, he has a more relaxed companion: a “lazy king poodle,” Janosh. Even though he retired 25 years ago, Mr. Klaus still keeps his employee badge and frequently visits the company, working on various projects. And rest assured, he remains the center of attention. Watchmakers, developers, project managers, and marketers alike greet him with a friendly “Grüezi” or “Hello, Mr. Klaus” as he strolls through the hallways. To them, he is a GOAT of watchmaking, a wealth of engineering expertise. Everyone is eager to learn from him, and he’s happy to continue contributing to IWC’s projects.

In celebration of Kurt Klaus’ 90th birthday in 2024, The JOURNAL organized a conversation between two generations united by a shared passion: watchmakers Kurt Klaus, inventor of the IWC Perpetual Calendar, and Markus Bühler, known for the iconic Big Pilot’s Watch with its turbine-inspired subdial. Find out Join them as they reflect on the past and present of watchmaking.

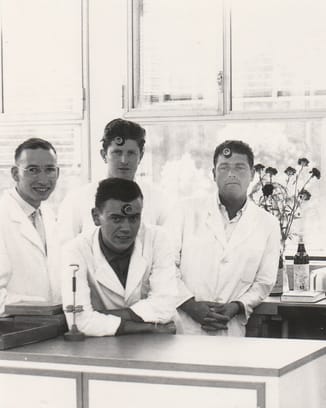

IWC HQ BACK THEN

Markus Bühler: You come from Sankt Gallen too, right?

Kurt Klaus: Yes, and my wife too. After watchmaking school, I worked in La Chaux-de-Fonds over in western Switzerland. Then I moved to Grenchen, and she visited me there quite a lot. So, we talked about getting married very early on, and she just goes: “Sure, I’d love to get married. But not in Grenchen, please!”

MB: [Laughs] Because it’s always so foggy there in winter...

KK: You’re not wrong, and I didn’t disagree. So, we went to eastern Switzerland.

MB: What was IWC like at the time?

KK: The current building on Baumgartenstrasse was the main one even back then. You could find the production department on the first floor, to the left and right of the main entrance. On the left was the ébauche department [watch component production] - that’s what we called it because back then we spoke a lot of French at IWC. We also had some brilliant mechanically controlled machines. Proper automatic machines that milled the base plates and bridges.

MB: I think back on those machines quite often. They were relatively small, and each one was used to perform a specific task.

KK: Ah yes, back then you needed a different machine for every single work step. However, they seemed pretty big to me at the time. There was also a tool production department at the right of the main entrance. That was very important to me. I always needed special tools to create prototypes. I was even lucky enough to have my own turning machine.

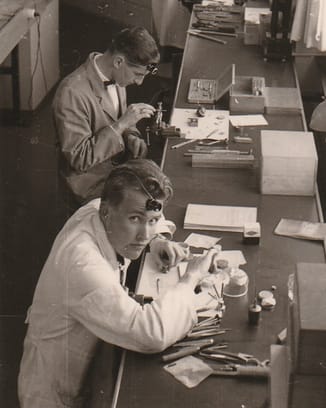

The offices were up on the second floor, just like they are now. And in the wing facing the Rhine was the watchmaking workshop. I worked right up there on the top floor. With a view over the Rhine, it really wasn’t too bad! Our movement assembly was also there. We had a long table by the window, and we’d all sit together, side by side, working away.

MB: Almost like today’s version of the line assembly…

KK: Yes, I guess you could say that, but we weren’t really that systematic. I started working there on January 2, 1957.

EXCELLENCE ABOVE ALL

MB: Like you, I also worked as a prototype engineer at IWC. This role has always been an important step in the creation of new movements. Were you hired as a prototype engineer?

KK: No, I came to IWC as just your regular watchmaker. All I really wanted to do was make watches. After doing pretty well at school, I introduced myself to Albert Pellaton. He thought my results were excellent but said: “You know, an IWC watchmaker works to a higher standard.” He was a perfectionist, that one. So, I came to IWC as a beginner, assembling wheel trains. Back then, manufacturing tolerances weren’t as tight as they are today. Sure, we did calculations down to the nearest hundredth and thousandth of a millimeter. But, the wheels had more height game, and we had to adjust that. This was part of the watchmaker’s job.

[Kurt Klaus’ eyes start to sparkle.] During the finishing process, we used a device to adjust the height game. It was a block, a potence, on which the piece was placed. You would then pull a small lever so that the stone would slowly move upwards and the height game would become smaller and smaller. Finally, the inspector would come around and check it all.

MB: This interim inspection still exists today – we call it an in-process control. Nowadays, we no longer determine the height game by eye but with a measuring machine. This lifts all the pinions of the wheels and measures the height game. This way, the watchmaker knows how much game the minute wheel needs. It's funny to think that the play used to be set in the finished wheel train. We correct it separately now.

KK: Yeah, we would have to pull a lever. It slowly pushed the stone upwards into the plate and whoosh... job done.

“THINGS ARE JUST GETTING STARTED”

MB: How did IWC stand out from the other watch brands back then?

KK: As Albert Pellaton used to say, “The work of an IWC watchmaker is always to a higher standard.”

MB: I had a similar experience 23 years ago. I was able to complete my apprenticeship at IWC with a pretty good grade and was hired as a prototype watchmaker. Ronald Jäger [the production manager] said: “You got great results, but things are just getting started.” And he was right - the challenges were huge. The demand for durability and water resistance has increased too, which makes the development of new movements very challenging.

KK: Yes, that’s right.

MB: How many colleagues worked on the development of the perpetual calendar?

KK: [smiles and points to himself] I more or less designed the whole thing myself. I made the components using this brilliant drilling machine we had. Bet that thing doesn’t even exist anymore!

MB: Yeah, I remember that one. It used to be in the training workshop. I also used it to make my tourbillon. It was very precise.

KK: I came to really love that machine. I could use it to make anything! I even used it to make the entire module plate for the first perpetual calendar - in other words, everything! Milling, drilling,...

MB: That’s quite the achievement! Today, it’s hard to imagine developing components without a CNC machine. When we develop a new movement, everything starts with the developer, but all the departments that will later manufacture the product are involved from the outset. From the very first step, it’s crucial to ensure that, on the one hand, we can use state-of-the-art machines and, on the other hand, that the entire process—quality controls, sourcing parts, you name it—is monitored from the very beginning. This is the only way to guarantee optimum production at all times.

Plus, we’ve got to think about the industrialization of the movement assembly at an early stage: the first base plate, the train bridge, the components – everything should be able to be disassembled and assembled in 3D on the computer ahead of time. This allows the watchmaker to check whether or not they can assemble it and spot any potential hiccups. [Kurt Klaus chuckles]

KK: The most exciting thing for me is being able to witness watchmaking then and now and to see how IWC continues to develop year after year. It truly is an extraordinary experience in the craft of watchmaking!

THE JOYS OF ASSEMBLY AND ULTRASONIC CLEANING BATHS

MB: Which job did you enjoy the most?

KK: In the beginning, it was basic watchmaking. The ability to fully assemble a timepiece and then see it work perfectly. For me, that was the pride of watchmaking. The same goes for repairs and when we worked with ultrasound for the first time - it was the most cutting-edge technology at that time.

MB: The ultrasonic cleaning bath...

KK: Exactly, a big ultrasonic cleaning bath for all watch parts. As service watchmakers, we took the movement apart, put all components in an ultrasonic cleaning bath, and then reassembled them. We called it the “Wäschchuchi” [Swiss German for “laundry room”]. Mr. Pellaton wasn’t too happy when he heard that, though.

MB: [laughs] Yep, I can just picture his face. How does it make you feel when you see someone wearing your perpetual calendar on their wrist?

KK: I get an incredible sense of satisfaction. The perpetual calendars we have today are basically identical to what I drew back in the ‘80s. They never went away. They are still around today. Even after 40 years. The functions remain the same - but fortunately, they have been updated. This year, the Eternal Calendar was introduced. What a marvelous piece of work!

ACHIEVING A LOT WITH FEW RESOURCES

MB: In the past, only a few tools were available to you, such as a logarithm table. You achieved a lot with very little, in turn making our perpetual calendar stand out: it can be adjusted via just one single crown. This approach of achieving a lot with very little still shapes our thinking today. We always ask ourselves what components are really needed to create a function.

KK: I only discovered later that you could actually calculate logarithms with a calculator. So, I picked up one of those HP pocket calculators. It included all the trigonometric functions in there. So, since then, I’ve completely forgotten the logarithm table!

[Markus pulls out his smartphone and shows an app with the HP calculator.]

MB: Today, I’m still able to work exclusively with this digital version of an HP calculator.

KK: Yes, that’s how digitalization found its way to me. When you look at watchmaking today compared to 70 years ago, it really isn’t all that different. Watching the watchmakers at their tables, carefully inserting the wheels with tweezers, takes me back to when I did the same thing 70 years ago. Back then, though, I was still filing those levers by hand!

MB: That’s true, a lot is still the same, but today we have more digital support. With modern CNC machines, wire erosion, and 3D printing, prototypes that previously had to be made by hand can be produced much faster. Without these technologies, the development of Ceratanium® wouldn’t have even been possible.

I could talk with you for hours, but to wrap up our conversation, I have a personal question: have you ever met up with colleagues outside of work?

KK: I can still remember a Christmas dinner at the Hombergerhaus. We had Fleischkäse with Rösti. And I played tennis at the IWC sports club. But honestly, outside of work, I wasn’t much of a social butterfly. I guess I was a bit odd in that respect. For five years, I pretty much viewed the world like this [mimics the posture of a watchmaker] until the perpetual calendar was finished. My family was my whole world. I joined IWC on January 2, 1957, and got married on March 2, 1957. By January 1958, our first son was born. From then on, it was all about family for me.

After the interview, a few headshots of Mr. Klaus are taken. While the photographer prepares the background, Mr. Klaus checks his e-mails on his smartphone - he doesn’t waste a single minute. He has fully embraced the digital age now and is all ears when creative ideas are thrown his way. “I’m always very happy to help,” he says. Nevertheless, he’s already looking forward to slipping into his comfy Finken [Swiss German for slippers] in the evening and whipping himself up a delicious meal. Tomorrow, he’ll focus on his second great passion: his garden. Pruning bushes isn’t his thing, but he loves planting and caring for flowers. As for his 90th birthday? He marked it the same as always - quietly, with just his two kids and his king poodle, Janosh.